3D Printing – #TheAdditiveMovement

High Quality Parts Manufacture with Rapid Turnaround

BlueZone is pleased to join the #TheAdditiveMovement with 3D Printer supplier Markforged featuring BlueZone engineering work on their website:

The BlueZone Group engineering team have kept the Markforged carbon fibre / composite 3D printer busy at the Perth workshop. Printing with Carbon Fibre, Fiberglass, and Kevlar the ability to produce printed parts with the strength of metal has turbo-charged hardware engineering development for BlueZone customers.

The Markforged Printer capability has been used to support customers with rapid prototyping capability and also to complement the existing UVS cable moulding and subsea capable assembly capability:

Often in high demand for quality component supply, UVS engineers have investigated and tested the available printer materials for subsea applications and can assist with design options for urgent projects.

The Markforged Mark Two 3D Printer can print in advanced materials including composite materials with a higher strength-to-weight ratio than 6061-T6 Aluminium:

- Carbon Fibre – highest strength-to-weight

- Kevlar – highest abrasion resistance

- Fiberglass – highest strength-to-cost

- Nylon – tough engineering plastic

- Onyx – stiff, micro-carbon fiber nylon

- High Temperature Fiberglass – ideal for applications that need material with a higher temperature deflection point

Read More:

Additive Manufacturing at BlueZone Group

3D Printing – High Quality with Rapid Turnaround

|

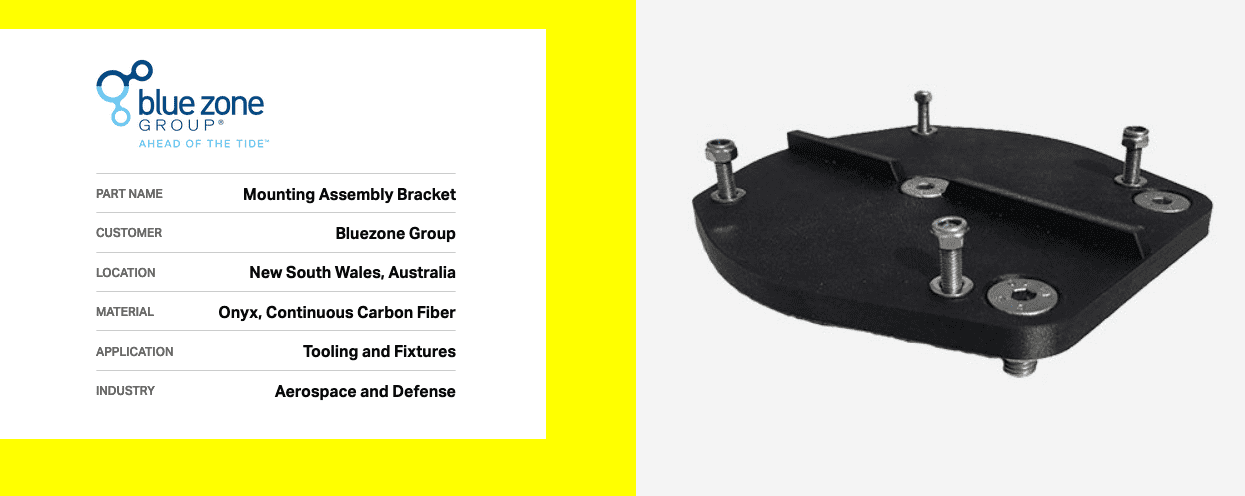

| Sound Velocity Profiler Mounting Assembly Bracket from Onyx. |