3D For Subsea

BlueZone Group is excited to announce the acquisition of a an engineering-grade Desktop 3D Printer to complement the engineering capability of the BlueZone Group team.

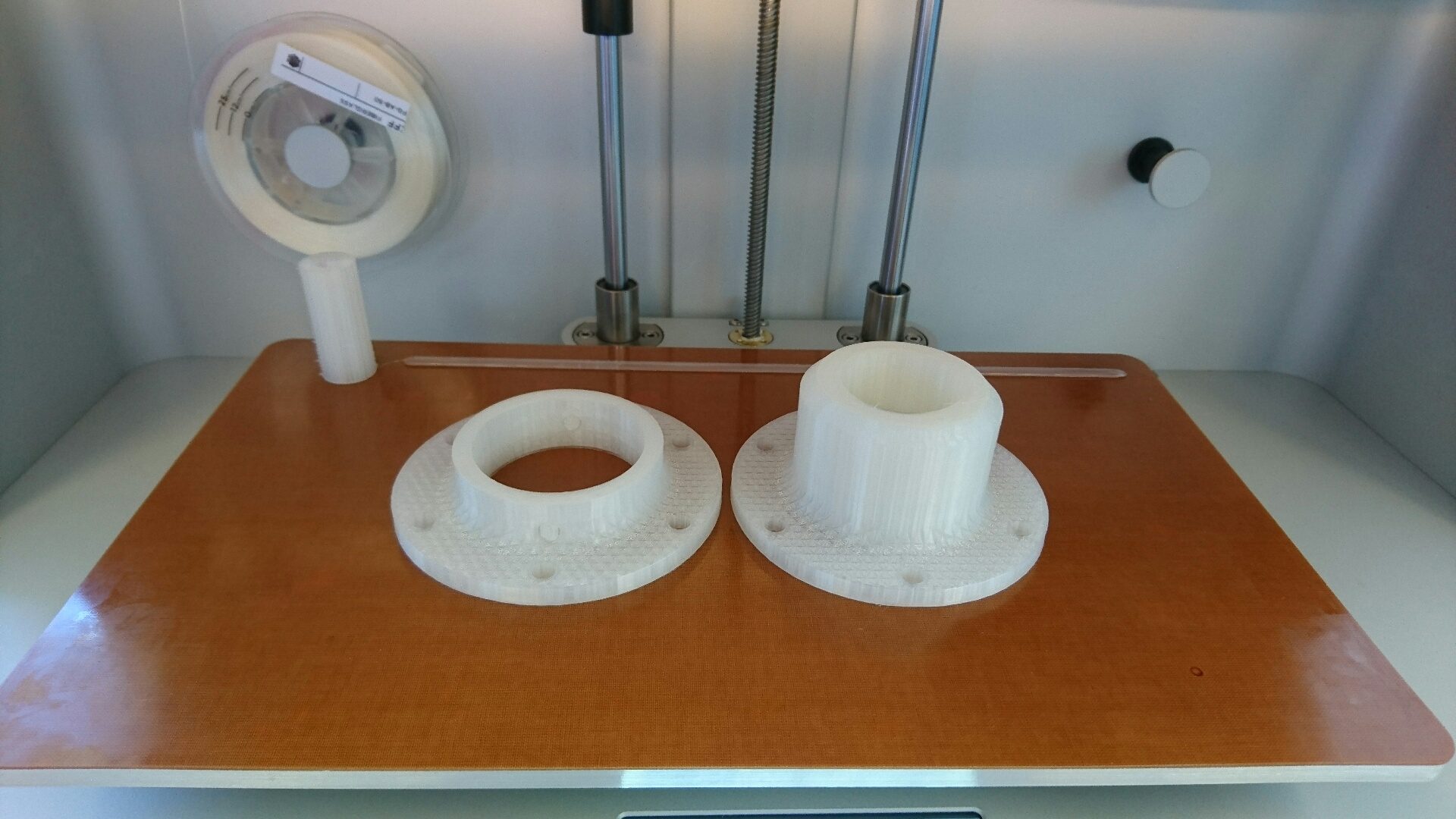

BlueZone Group CTO, Darren Burrowes, said that the engineering team had been actively monitoring the 3D Printer market for some time and had selected the Markforged Mark Two industrial strength 3D printer for its ability to go straight from 3D models to strong, stiff parts suitable for prototype and production.

“The 3D Printer capability will enable BlueZone to meet our customers needs in more rapid and more innovative ways,” said Darren, “Many of our customers are seeking fast development of one-off products for specialised underwater applications and the Markforged Printer will give the engineering team new options for fast-turnaround solutions.”

The Markforged Printer capability has been initially established at the BlueZone UVS Perth office where it will be used to support customers with rapid prototyping capability and also to complement the existing UVS cable moulding and subsea capable assembly capability https://bluezonegroup.com.au/services/polyurethane-moulding-service that it often in high demand for quality component supply. UVS engineers will investigate and test the available printer materials for subsea applications.

The Markforged Mark Two can print in advanced materials including composite materials with a higher strength-to-weight ratio than 6061-T6 Aluminium:

• Carbon Fiber – highest strength-to-weight

• Kevlar – highest abrasion resistance

• Fiberglass – highest strength-to-cost

• Nylon – tough engineering plastic

• Onyx – stiff, micro-carbon fiber nylon

• High Temperature Fiberglass – ideal for applications that need material with a higher temperature deflection point

Prototype bracket for a Tide Gauge