ClearSignal® Coating for Biofouling Prevention in Offshore Oil & Gas

Toughness and Adhesion to the Substrate Enables Robust Cleaning

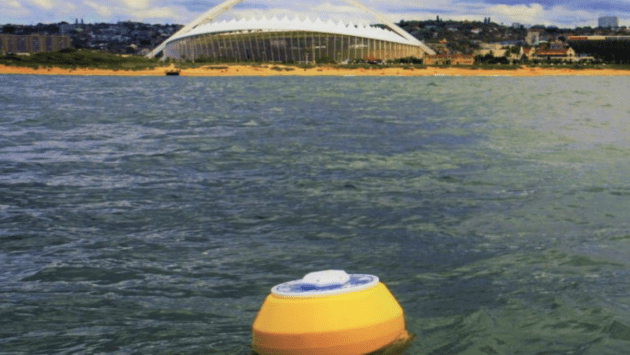

The ClearSignal® toughness and adhesion to the substrate is far superior to any other foul release coating and this enables ClearSignal® to be cleaned in a robust manner. This was a key design parameter for ClearSignal®. Robust cleaning is essential for long term application such as for subsea instruments and equipment used in Offshore Oil & Gas applications where periodic Inspection, Maintenance and Repair (IMR) activities are achieved using Remotely Operated Vehicles.

The ClearSignal® biofouling control system has undergone several testing and evaluation procedures to qualify the coating for in-air and in-water, pressure cleaning using water jetting. The substrates tested include hard rigid plastics, rigid metals and coated fabrics.

The optimised water pressure cleaning system removes accumulated biofouling in the least amount time possible without any damage or degradation to the ClearSignal® coating. The spray nozzle type, nozzle distance to device being cleaned and volume of water used in the spray all effect the balance of efficiency of cleaning verses damage to the coating.

For the general case of cleaning submerged Offshore Oil & Gas structures coated with ClearSignal® using an ROV operated water jet operating at 3000 P.S.I, the control variable for optimal operation is the nozzle distance to the ClearSignal® coated structure. It is predicted that a distance of 75 to 300mm to the structure is acceptable. The exact minimum nozzle distance to use at the 3000 P.S.I. with no coating damage is best determined through a controlled trial.

Read More

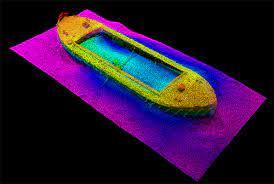

ClearSignal® Coating Under Test

ClearSignal® for Long Term Biofouling Protection

|

| High quality finish achieved using ClearSignal® Coating for subsea structure enables robust cleaning using ROV operated water jet. |

|

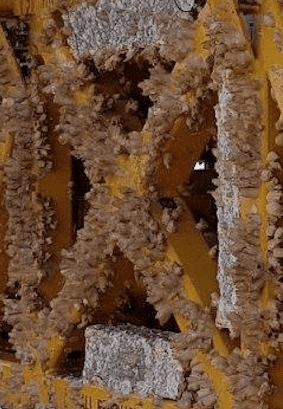

| Biofouling on Subsea Offshore Oil & Gas Equipment prior to treatment with Clear Signal anti-biofouling coating. |