MARKETS

Case Study: Camera Enclosures for Harsh Environments

We are an Australian company with a growing international reputation

focusing on the design and servicing of high quality underwater

electronics used in harsh environments.

Underwater experience ensures a reliable solution

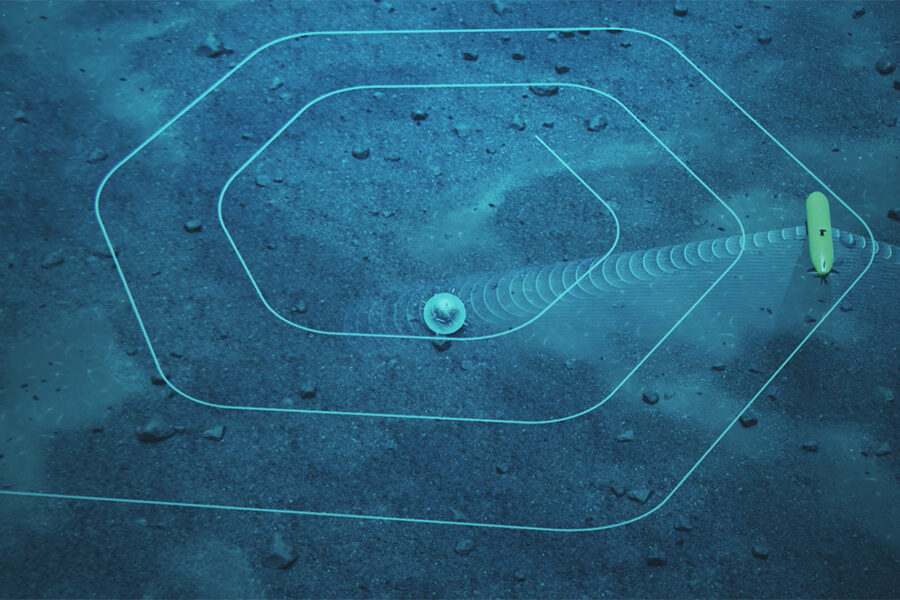

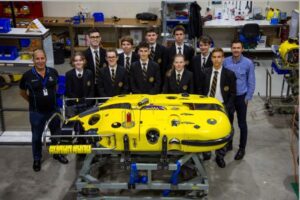

As machine vision cameras and hardware are increasingly deployed in industrial and harsh environments, many users have the need to package their equipment for long-term survivability. BlueZone engineering is founded on the need to package equipment for some of the harshest environments that are encountered – deep sea deployment for Offshore Oil & Gas and other demanding subsea applications.

The Water Corporation of Western Australia tasked BlueZone with the requirement to design and manufacture camera housings for eight Teledyne Dalsa Genie T2041 cameras and complete with Kowa 6mm lens. The application was for mounting the cameras on a pipeline crawler for long-distance inspection of partly flooded pipelines. Both the housings and associated junction tubes needed to be as space efficient as possible. Both were designed to be waterproof to 100 m depth and a hard-anodised finish on both items was required.

The cabling arrangement included mounting four cameras with ethernet pass-through, four serial conductors and power supply conductors. The four power pairs (eight conductors), were combined inside the junction tube and a standard hose fitting was used on one end to pass through four cameras and the combined power cable.

We are an Australian company with a growing international reputation

focusing on the design and servicing of high quality underwater

electronics used in harsh environments.

BlueZone’s approach was to build on the CC03 High Definition Drop Camera design for underwater seabed inspection to depths of 100m. The proven reliability and capability of this design were a good starting point for a camera enclosure for harsh conditions.

Full advantage of in-house 3D printing capability was taken for rapid design and manufacture of a specialised mounting bracket. This bracket enabled infinite rotation of the camera inside the housing for required alignment between cameras to support image stitching software.

Read More: High Quality and Rapid Turnaround 3D Printing for Subsea Applications

Featured Products

Kraken’s KATFISH is an advanced, actively stabilized Synthetic Aperture Sonar (SAS) towfish system engineered to deliver exceptional seabed intelligence

Read moreLatest News

Advancing ASW Readiness with SEABER’s RECALL® Micro AUV

As naval undersea threats grow more sophisticated, the demand for smarter, safer, and more realistic operator training has never been greater. As undersea warfare becomes increasingly complex, navies must...

Read MoreFrom Depths to Discovery: Xeos Petrel X3 Enhances Oceanographic Operations

As oceanographers push deeper into uncharted waters, the Xeos Petrel X3 emerges as a vital lifeline; ensuring that even the most remote underwater assets find their way home. In the...

Read MoreSeeTrack: The Defence Ready Command and Control System for Maritime Autonomy

In an era where robotic systems define naval superiority, SeeTrack stands at the centre: Uniting AUVs, ROVs, and operators into one powerful defence ecosystem As autonomous technologies reshape the...

Read MoreDeepSea Power & Light We would like to inform you that the SeaLite Sphere SLS‑7200 has officially reached end‑of‑life and is no longer in production. This decision follows the...

Read MoreCamera Enclosures for Harsh Environments

Underwater experience ensures a reliable solution

As machine vision cameras and hardware are increasingly deployed in industrial and harsh environments many users have the need to package their equipment for long-term survivability. BlueZone engineering is founded on the need to package equipment for some of the harshest environments that are encountered – deep-sea deployment for Offshore Oil & Gas and other demanding subsea applications.

The Water Corporation of Western Australia tasked BlueZone with the requirement to design and manufacture camera housings for eight Teledyne Dalsa Genie T2041 cameras and complete with Kowa 6mm lens. The application was for mounting the cameras on a pipeline crawler for long-distance inspection of partly flooded pipelines. Both the housings and associated junction tubes needed to be as space-efficient as possible. Both were designed to be waterproof to 100m depth and a hard-anodised finish on both items was required.

The cabling arrangement included mounting four cameras with ethernet pass-through, four serial conductors and power supply conductors. The four power pairs (eight conductors) were combined inside the junction tube and a standard hose fitting used on one end to pass through four cameras and the combined power cable

BlueZone’s approach was to build on the CC03 High Definition Drop Camera design for underwater seabed inspection to depths of 100m. The proven reliability and capability of this design were a good starting point for a camera enclosure for harsh conditions.

Full advantage of in-house 3D printing capability was taken for rapid design and manufacture of a specialised mounting bracket. This bracket enabled infinite rotation of the camera inside the housing for required alignment between cameras to support image stitching software.

Read More:

High Definition Drop Camera for seabed inspection

High Quality and Rapid Turnaround 3D Printing for Subsea Applications