Subsea Electronics Modules

Subsea Electronics Modules

BlueZone continues to meet demand from Offshore Oil & Gas and Ocean Renewable Energy customers for Subsea Electronics Modules (SEM) that enable deployment of electronic systems and sensors to all ocean depths.

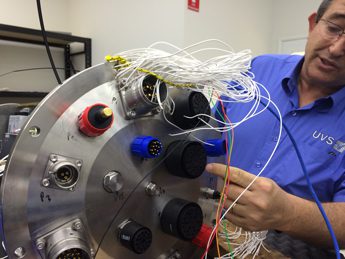

General Manager, Offshore Oil & Gas, Mark Musarra, said that the design of SEM needed to consider many factors and that UVS experience over many years assured customers of a reliable and fit-for-purpose product. “One consideration that is key to SEM design is real estate on the module housing for positioning of underwater connectors”, said Mark, “BlueZone has access to a wide range of connectors from many OEMs and the selection of the right connector for the application can ensure optimisation of the SEM connector plate layout”. This can mean an overall smaller size for the SEM and reduced costs for providing the same capability. The smaller SEM is easier to handle, deploy and recover.

BlueZone standard designs for SEM housings have been proven for many applications and by working with local manufacturers rapid optimisation and manufacture can be accomplished for Australian customers. “Available raw material sizes constrain SEM options in Australia” said Mark, “By working closely with customers we can advise on options to take advantage of cost effective use of locally available materials for subsea applications”.

|

|

|

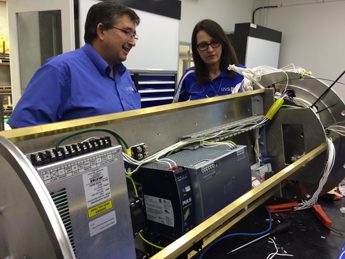

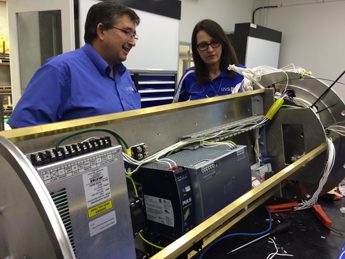

| Mark Musarra identifies a Seacon Brantner All-Wet Split Series connector by that provided an ideal solution for a customer application | Mark Musarra and Gunilla Burrowes (Chair of UVS Research and Innovation Committee) inspect an SEM in manufacture at UVS Perth |