PMI Industries’ DAM/BLOK™ Subsea Electrical Cable Splice Kits

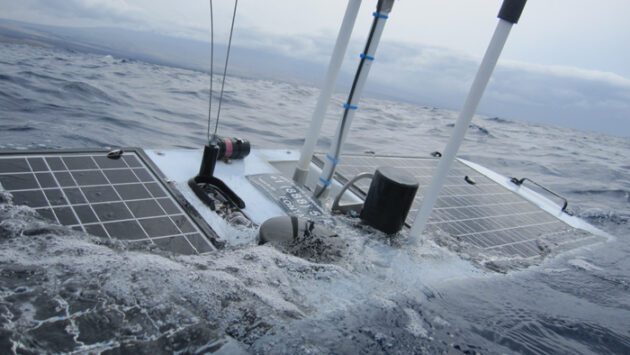

The marine environment can be treacherous. The environment poses many challenges including extreme pressure, high salinity, ever-changing environments etc, so ensuring equipment is reliable and keeping the water out is essential.

BlueZone Group has been partnering with PMI Industries for many years due to their high-quality products and excellent customer service. PMI Industries are specialists in designing, manufacturing, and testing underwater cable hardware and assemblies. They are a worldwide supplier for custom cable systems, cable hardware, and protection devices for marine cable applications such as the production and development of Submarine Tactical Array Sonar System (STASS) Tow Cables. PMI products are used in dynamic applications throughout various industries, with standard products available for a variety of cable sizes.

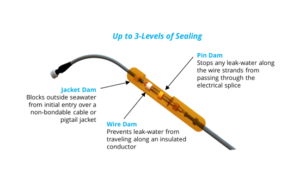

The DAM/BLOK™ Splice Kits are comprised of a unique combination of up to three levels of sealing protection that produce a highly, reliable, full-ocean depth pressure splice. The mechanical seals, chemical bonds, positive water blocking, and a polyurethane over-mold work together to prevent leaked water present in the cable, or seawater outside the cable from passing through the splice to the electrical connection.

Radial squeeze resulting from compression dams prevent any leaking water migrating along the non–bondable elements from passing through. No driving force present can overcome the persisting interference due to the isostatic nature of the seal (the same pressure exists on all sides of the seal). The DAM/BLOK Splice uses ambient pressure to prevent internal water migration. Currently, PMI have over 100 existing DAM/BLOK electrical splice kit designs or can custom design a splice kit to meet each requirement.

PMI are using 3D printing to explore new ways to provide engineering solutions to meet their customer’s needs. The 3D printing manufacturing technology improves the quality control and prototyping of crucial components which will reduce the assembly time. Terrence Mathis, PMI Engineering-Cable Protection Manager said “The PMI engineering team has used additive manufacturing to make solid three-dimensional objects from a CAD (computer-aided design) file for several years. Because fabrication materials are improving and becoming more cost-effective, we are investigating more ways we can apply the technology”.

For more information about PMI’s products or services, contact the sales or service team at BlueZone.

Read More:

3D Printing Offers New Ways for PMI to Solve Customer Challenges