ClearSignal® prevents biofouling

Trials demonstrate effectiveness in two oceans

ClearSignal® anti-biofouling coating continues to demonstrate its effectiveness in reducing the impact of biofouling on buoys and subsea structures deployed in diverse locations in the world’s oceans.

Buoy coating prevents fouling

In trials conducted with the Coastal Studies Institute in North Carolina, USA, comparison of one coated and one uncoated buoy showed significant reduction in biofouling on the coated buoy compared with the uncoated buoy.

ClearSignal® foul release coatings operating in static conditions such as a buoy deployment do in many cases require periodic cleaning. However, the energy and effort required to clean a high-performance foul release coating is minimal as fouling adhesion has been reduced by up to 97%. The degree of biofouling accumulation incurred varies with geography, seasonal variations in water conditions and associated biology, water depth and its associated light exposure.

Self-cleaning due to movement from waves can occur in some locations and has been observed on this trial. As the growth on the coated buoy reaches a critical mass it is more likely to self-clean as there is simply more force on the growth attachment points to the buoy. This phenomenon has also been observed on seismic streamers.

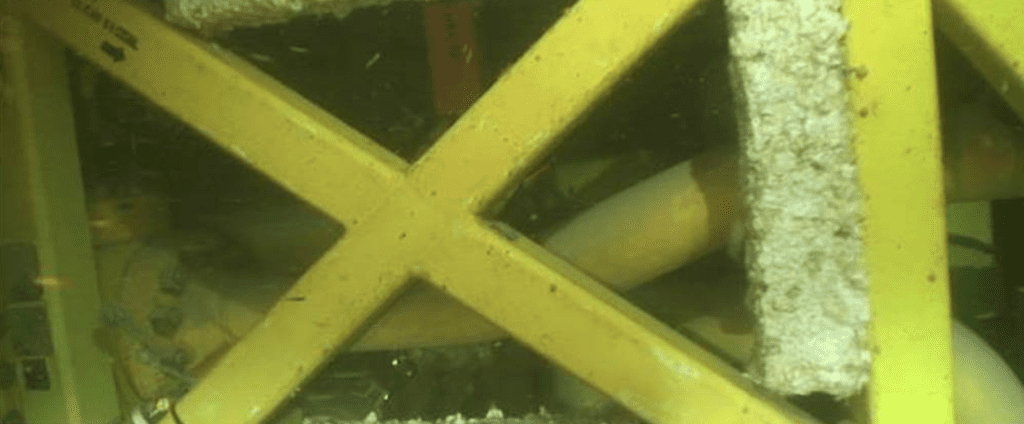

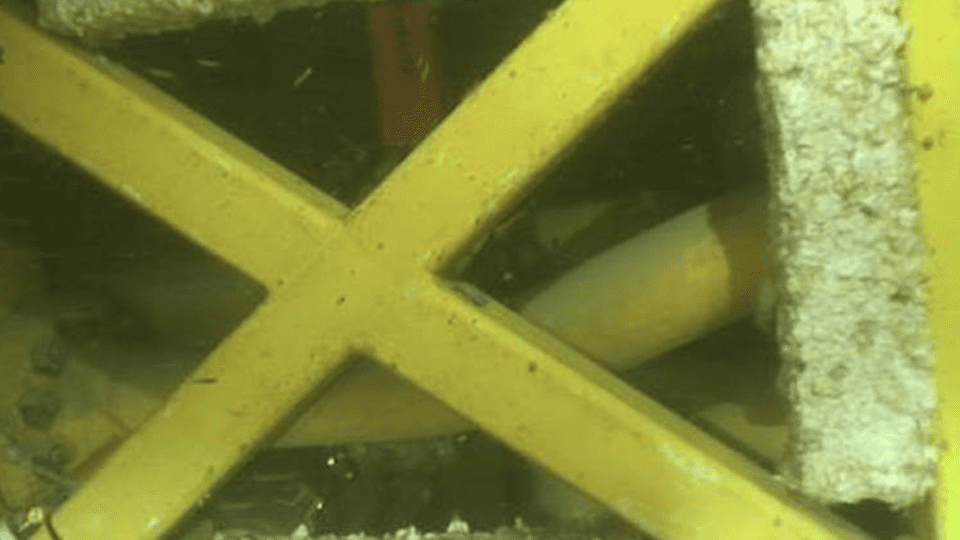

Subsea structures benefit from ClearSignal® coating

In another trial underway on Australia’s Northwest shelf, excellent results have been observed from coating applied to a subsea structure. The ClearSignal® coating is optically clear and so it does not obscure marking and labelling which is important for management and operation of subsea assets.

An important property for foul release coatings is that they must be highly durable and achieve high adhesion to the base substrate being coated to deliver years and even decades of biofouling protection. The durability and adhesion of the coating play an important role in the general survivability of the coating in the rigorous operating conditions of the marine environment. High durability and substrate adhesion also enable the coating to be cleaned in several different manners that range from water jets, mechanical cleaning, and exposure to natural high energy conditions such as surface waves.

ClearSignal® 30-year life span

The desired lifespan of ClearSignal® is 30 years.

The product is approximately 10 years old and while ClearSignal® has achieved high levels of success, a 30-year time series of testing does not exist. The manufacturer, Severn Marine Technologies, does have several case studies of long-term deployments where periodic inspections show excellent biofouling resistance and no deterioration of the coating system after long term immersion. The longest deployments to date are on the order of 10 years.

Severn Marine Technologies also conducts a continuously expanding systematic testing series of ClearSignal® coated test panels using of all the various substrates that are coated. The test plates are subjected to high levels of UV exposure to stress the coating and are then immersed in seawater. The samples are periodically tested for adhesion to the substrate and overall coating condition. The longest immersion for this ongoing testing is 10 years. The Severn Marine Technologies systematic series of testing described is very effective and has been shown to have a high correlation to the real-world use of ClearSignal®.

Read More

ClearSignal® coating for long-term anti-biofouling prevention