ClearSignal Coating Now Available in Australia

ClearSignal Coating Now Available in Australia

ClearSignal Coating Now Available in Australia

UVS is pleased to announce an agreement with Severn Marine Technologies, LLC Annapolis, MD and Mid Mountain Materials Inc. of Mercer Island, WA.

ClearSignal coating products will be able to be applied to your instruments and underwater components at the UVS workshop in Newcastle, Australia from mid-July. This will enable a fast turnaround of instrument coatings and UVS will be pleased to offer ClearSignal coating as an option together with ADCP Silver Service verification.

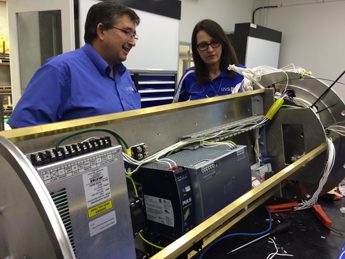

The agreement will enable UVS technicians trained in the application of ClearSignal coatings. The system is applied in a controlled facility using state-of-the-art industrial processes. The intended substrate and application methods are significant engineering design components of the ClearSignal system. The product formulation is also adjusted for the particular marine application.

“Biofouling control is a key consideration for the deployment of marine instruments, and specialised platforms used for scientific, military and commercial oceanographic sensing”, said UVS CTO Darren Burrowes, “The ClearSignal coating method is a breakthrough permanent protection for marine instrumentation and specialised long term immersion platforms such as gliders and underwater barriers”.

“Biofouling conditions in Australian seas are among the worst in the world”, said Darren, “Mooring deployment times in some locations can in fact be limited by biofouling concerns when there is a high risk that an acoustic release can be jammed by marine growth”. ClearSignal is ideal for treatment of all types of instruments and systems where biofouling is a deployment limiting issue.

Unlike anti-fouling systems that rely on active biocides and whose effectiveness degrades with time, ClearSignal remains 100% effective for the intended life of the instrument.

|

|

ClearSignal is ideal for treatment of instruments such as ADCPs and will eliminate downtime caused by biofouling. It remains 100% effective for the life of the instrument. |